Nationwide Parts and Services

Preventative Maintenance for Clamshell Platen PressesClamshell platen presses are workhorses in the die cutting industry. Whether you use yours for packaging, printing, or specialty applications, proper maintenance is the key to consistent performance and reduced downtime. Too often, companies wait until breakdowns occur — leading to costly interruptions. A preventative maintenance plan is the smarter choice.

Preventative Maintenance for Clamshell Platen Presses

Daily and Weekly

Maintenance Checks

Operators should regularly inspect:

-

Lubrication points – Keep all moving parts properly lubricated.

-

Bolts and fasteners – Ensure nothing has loosened under vibration.

-

Die bed alignment – Misalignment can cause uneven cuts and damage.

-

Electrical connections – Check for wear or overheating.

Preventative Maintenance for Clamshell Platen Presses

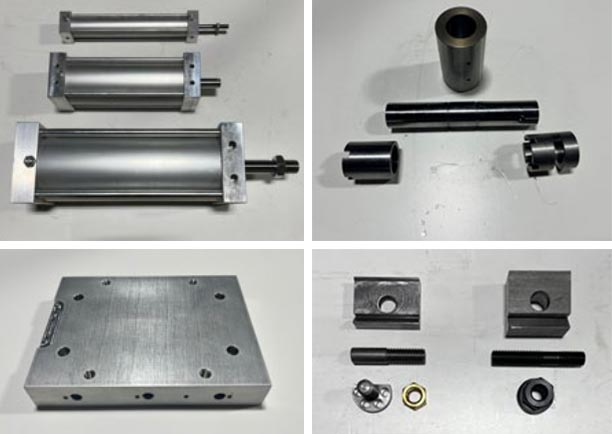

The Role of OEM Parts

Using OEM parts designed specifically for Kensol-Franklin, Thomson, and Perkins presses ensures compatibility, reduces wear, and keeps your equipment running at its best. Aftermarket or generic parts often result in premature failures.

Partnering with Professionals

Nationwide Parts and Services offers preventative maintenance, expert repairs, and full rebuilds. Our technicians understand both the machines and the die cutting processes — allowing us to diagnose and fix issues faster than local mechanics.

Request Service or Get a Quote

Preventative maintenance isn’t just about avoiding downtime — it’s about optimizing your press for years of reliable use. By combining operator checks with professional service and OEM parts, you’ll keep your clamshell platen press working at peak performance.

Kensol Franklin Hot Stamping Presses

Support and Parts

Thomson Value Line

Standard Die Cutters

Preco Clam Shell Style

ITM

Cauhe

Crest

Contact Us

Nationwide Parts and Services

1 Main Street

Suite 5

Whitinsville, Ma 01588

Phone: 508-528-2000

Email: contact@nationwidepas.com