Nationwide Parts and Services

Die Cutter Problems and SolutionsEven the most durable die cutting machines experience performance issues over time. From misalignment to electrical faults, small problems can quickly snowball into production downtime. Knowing how to identify and address these common issues helps operators stay ahead of failures — and keeps your Thomson die cutter running at peak performance.

Die Cutter Problems and Solutions

1. Incomplete or Uneven Cuts

Uneven or shallow cuts often point to die bed misalignment, worn cutting surfaces, or inadequate pressure.

Operators should regularly inspect:

-

Lubrication points – Keep all moving parts properly lubricated.

-

Bolts and fasteners – Ensure nothing has loosened under vibration.

-

Die bed alignment – Misalignment can cause uneven cuts and damage.

-

Electrical connections – Check for wear or overheating.

Solution

Verify alignment, check for worn dies, and confirm press pressure settings. If cutting inconsistency continues, professional recalibration is recommended to restore proper tolerances.

Die Cutter Problems and Solutions

2. Press Hesitation or

Slow Cycling

A press that cycles unevenly or slows down mid-operation could have lubrication issues, worn bushings, or mechanical friction.

Solution

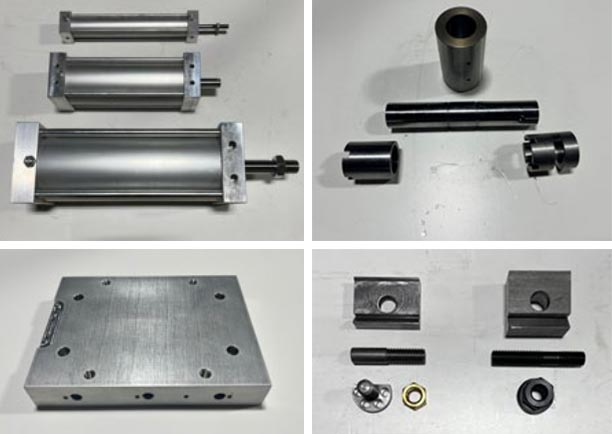

Follow a consistent lubrication schedule and inspect all motion components. Replace worn bearings or linkage arms with genuine OEM parts to restore original responsiveness.

Die Cutter Problems and Solutions

3. Electrical Malfunctions

Electrical problems can cause intermittent cycling, inconsistent pressure, or complete stoppages.

Solution

Inspect wiring for wear, confirm relay function, and check for overheating. Replace electrical components only with manufacturer-approved parts to maintain safety and consistency.

When to Call a Professional

If problems persist after basic troubleshooting, it’s time to bring in an expert.

Nationwide Parts and Services provides complete Thomson die cutter diagnostics, part replacement, and press restoration. Our technicians know these machines inside and out — helping operators extend lifespan and minimize downtime.

Kensol Franklin Hot Stamping Presses

Support and Parts

Thomson Value Line

Standard Die Cutters

Preco Clam Shell Style

ITM

Cauhe

Crest

Contact Us

Nationwide Parts and Services

1 Main Street

Suite 5

Whitinsville, Ma 01588

Phone: 508-528-2000

Email: contact@nationwidepas.com