In this guide, we will explore the different types of hot stamping machines, their applications, benefits, and key factors to consider when purchasing one. Whether you are a seasoned professional or a novice, this comprehensive guide will help you make an informed decision when investing in hot stamping machines.

Understanding Hot Stamping Machines:

What are Hot Stamping Machines?

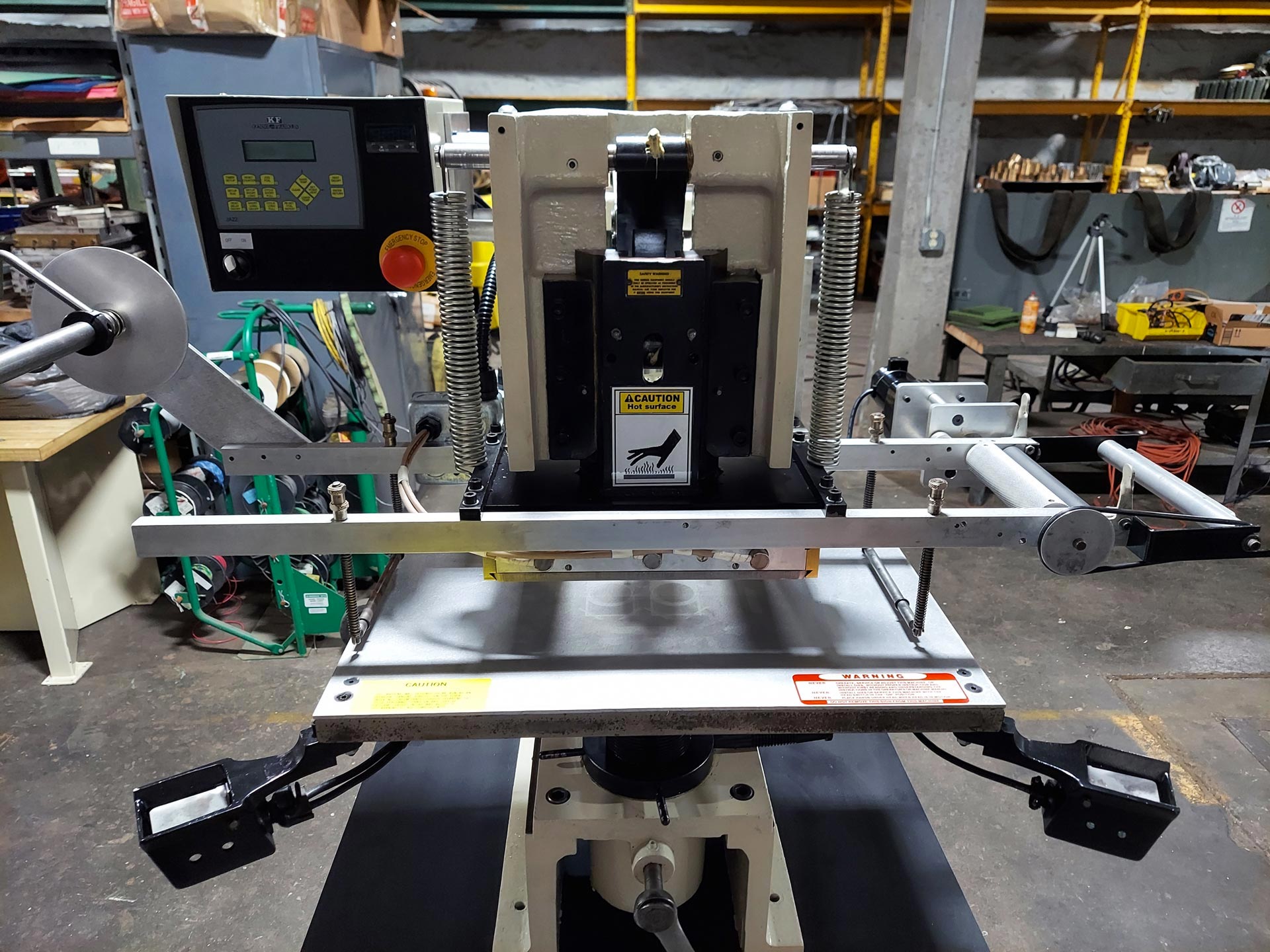

A hot stamping press is a machine used for printing or decorating various materials such as paper, leather, plastic, and fabric. This type of press uses heat and pressure to transfer a metallic or pigment foil onto the surface of the material. The foil is usually pre-printed with a design or logo. Hot stamping presses are commonly used in the manufacturing of items such as book covers, labels, packaging, automotive parts, and fashion accessories.

We offer hot stamping press / machines from Kensol Franklin.

Understanding Hot Stamping Machines:

What are Hot Stamping Machines?

A hot stamping press is a machine used for printing or decorating various materials such as paper, leather, plastic, and fabric. This type of press uses heat and pressure to transfer a metallic or pigment foil onto the surface of the material. The foil is usually pre-printed with a design or logo. Hot stamping presses are commonly used in the manufacturing of items such as book covers, labels, packaging, automotive parts, and fashion accessories.

We offer hot stamping press / machines from Kensol Franklin.

How do Hot Stamping Machines Work?

Hot stamping machines are used to apply a decorative metallic or colored film onto various surfaces, such as paper, plastic, leather, or fabric. Here is a general explanation of how these machines work:

1. Heat Transfer: The hot stamping machine consists of a heated metal plate, called a die, which has the desired design or pattern engraved on it. The die is typically made of brass or other heat-resistant materials. This die is heated to a specific temperature, generally between 100°C and 200°C (212°F to 392°F).

2. Foil Placement: A roll of metallic or colored foil is placed on top of the material to be stamped. The foil is usually made of polyester film with a layer of adhesive on the underside. The foil comes in various colors, finishes, and effects, depending on the desired decorative effect.

3. Pressure Application: The die is brought down onto the material, with the foil sandwiched in between. The machine exerts pressure, which causes the heated die to come into contact with the foil and the surface material. The pressure, combined with the heat, activates the adhesive layer on the foil, causing it to stick to the material. The heat also softens the foil, allowing it to transfer its color or metallic properties to the material.

4. Peeling off: After a few seconds of applying the pressure, the die is lifted away, leaving behind the stamped design. The foil that has adhered to the material gets peeled off, while the remaining foil on the roll is wound back, ready for the next stamping operation.

Hot stamping machines can be manual, semi-automatic, or fully automatic, depending on the complexity of the operation and the requirements of the industry. They are commonly used in industries like printing, packaging, leather goods, and others that require high-quality decorative finishes on their products.

Note that different hot stamping machines may have variations in their operation, temperature settings, and specific features depending on the manufacturer and the intended application.

How do Hot Stamping Machines Work?

Hot stamping machines are used to apply a decorative metallic or colored film onto various surfaces, such as paper, plastic, leather, or fabric. Here is a general explanation of how these machines work:

1. Heat Transfer: The hot stamping machine consists of a heated metal plate, called a die, which has the desired design or pattern engraved on it. The die is typically made of brass or other heat-resistant materials. This die is heated to a specific temperature, generally between 100°C and 200°C (212°F to 392°F).

2. Foil Placement: A roll of metallic or colored foil is placed on top of the material to be stamped. The foil is usually made of polyester film with a layer of adhesive on the underside. The foil comes in various colors, finishes, and effects, depending on the desired decorative effect.

3. Pressure Application: The die is brought down onto the material, with the foil sandwiched in between. The machine exerts pressure, which causes the heated die to come into contact with the foil and the surface material. The pressure, combined with the heat, activates the adhesive layer on the foil, causing it to stick to the material. The heat also softens the foil, allowing it to transfer its color or metallic properties to the material.

4. Peeling off: After a few seconds of applying the pressure, the die is lifted away, leaving behind the stamped design. The foil that has adhered to the material gets peeled off, while the remaining foil on the roll is wound back, ready for the next stamping operation.

Hot stamping machines can be manual, semi-automatic, or fully automatic, depending on the complexity of the operation and the requirements of the industry. They are commonly used in industries like printing, packaging, leather goods, and others that require high-quality decorative finishes on their products.

Note that different hot stamping machines may have variations in their operation, temperature settings, and specific features depending on the manufacturer and the intended application.

Types of Hot Stamping Machines:

- Manual Hot Stamping Machines

- Semi-Automatic Hot Stamping Machines

- Fully-Automatic Hot Stamping Machines

Applications of Hot Stamping Machines:

Packaging Industry:

– Enhancing product packaging with stunning designs and logos

– Adding labels, branding, and product information to packaging materials

Printing and Publishing Industry:

– Personalizing books, magazines, and marketing materials with foil accents

– Creating eye-catching covers and promotional materials

Automotive Industry:

– Customizing car interiors with hot stamped logos and designs

– Enhancing the overall appeal of car exteriors with decorative accents

Textiles and Apparel Industry:

– Adding metallic accents and designs to clothing and accessories

– Creating unique branding elements on garments and fabrics

Types of Hot Stamping Machines:

- Manual Hot Stamping Machines

- Semi-Automatic Hot Stamping Machines

- Fully-Automatic Hot Stamping Machines

Applications of Hot Stamping Machines:

Packaging Industry:

– Enhancing product packaging with stunning designs and logos

– Adding labels, branding, and product information to packaging materials

Printing and Publishing Industry:

– Personalizing books, magazines, and marketing materials with foil accents

– Creating eye-catching covers and promotional materials

Automotive Industry:

– Customizing car interiors with hot stamped logos and designs

– Enhancing the overall appeal of car exteriors with decorative accents

Textiles and Apparel Industry:

– Adding metallic accents and designs to clothing and accessories

– Creating unique branding elements on garments and fabrics

Benefits of Hot Stamping Machines:

Versatility and Flexibility:

– Easily adjustable for different materials, shapes, and sizes

– Compatible with various foils, including metallic and holographic options

High-Quality Results:

– Produces sharp and durable imprints with precise details

– Offers superior adhesion for long-lasting results

Time and Cost Efficiency:

– Faster production process compared to traditional methods

– Minimal waste as only the necessary foil is transferred

Increased Branding Opportunities:

– Elevates the visual appeal of products and packaging

– Enhances brand recognition and perceived value of goods

Benefits of Hot Stamping Machines:

Versatility and Flexibility:

– Easily adjustable for different materials, shapes, and sizes

– Compatible with various foils, including metallic and holographic options

High-Quality Results:

– Produces sharp and durable imprints with precise details

– Offers superior adhesion for long-lasting results

Time and Cost Efficiency:

– Faster production process compared to traditional methods

– Minimal waste as only the necessary foil is transferred

Increased Branding Opportunities:

– Elevates the visual appeal of products and packaging

– Enhances brand recognition and perceived value of goods

Key Factors to Consider when Purchasing Hot Stamping Machines:

Production Requirements:

– Assessing anticipated production volume and speed requirements

– Determining the desired level of automation for the workflow

Material Compatibility:

– Ensuring compatibility with the materials you plan to work with

– Assessing the thickness, texture, and heat resistance of the materials

Foil Variety and Availability:

– Determining the range of foils available for the machine

– Evaluating the accessibility and cost of acquiring specific foils

User-Friendliness and Training:

– Considering the ease of operation, required training, and technical support

– Assessing the availability of suitable training materials and resources

Hot stamping machines have become an essential tool for professionals across various industries, providing endless possibilities in enhancing product presentation and branding.

By understanding the different types, applications, benefits, and key factors to consider, you can confidently choose the hot stamping machine that best suits your needs and achieve exceptional results in your printing endeavors. Invest wisely and unlock the true potential of hot stamping machines in 2024 and beyond.

We carry a comprehensive line of Kensol Franklin Hot Stamping Machines and Parts.

Kensol Franklin Hot Stamping Presses

Support and Parts

Thomson Value Line

Standard Die Cutters

Preco Clam Shell Style

ITM

Cauhe

Crest

Contact Us

Nationwide Parts and Services

1 Main Street

Suite 5

Whitinsville, Ma 01588

Phone: 508-528-2000

Email: contact@nationwidepas.com